Last updated on July 9th, 2024 at 11:10 am

[vc_row][vc_column][vc_column_text]How much does it cost to build a new home from the ground up? The short answer is that it depends. You could spend as little as $30k on a prefabricated tiny home or into the millions for a luxury custom home. So many factors—such as the house type, size, location, features, and finishes—will determine whether you ultimately pay $80 for a square foot or $350.

In this guide, we’ll share the average costs of building different types of houses from prefab to log homes and break down the costs associated with each component. If you’re curious to learn about the home construction process, read our guide on how to build a custom home.

Average Cost to Build a House

Cost to Build a Custom Home

Cost to Build a Prefabricated Home

Cost to Build a Log or Timber Frame Home

Construction Cost Breakdown

Cost Breakdown for a Custom Home

Cost Breakdown for a Manufactured Home

Factors That Influence the Cost of Building a House

Size and Shape

Region and Location

Land Characteristics

Quality of Finishes

Additional Home Features

Green and Sustainable Elements

Average Cost to Build a House

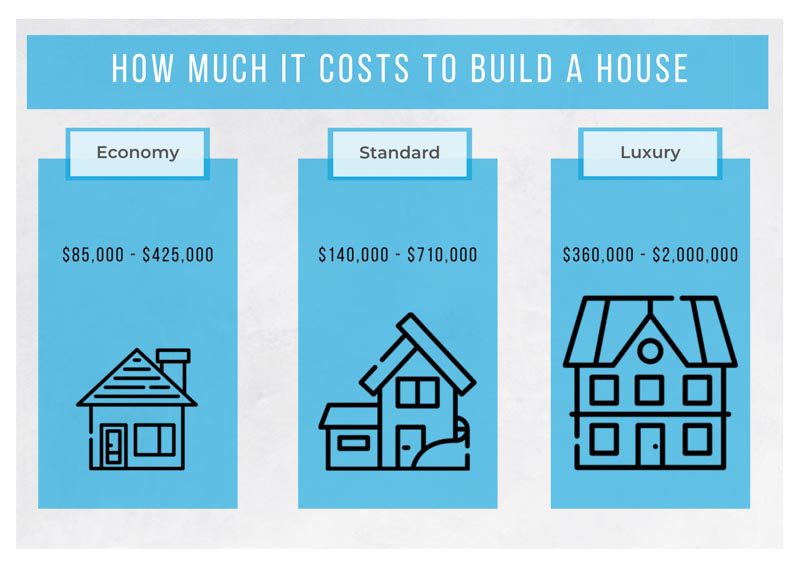

Get a free cost estimate The average 2,600-square-foot home in the U.S. costs roughly $400,000 or $150 per square foot. While the final cost when everything is tallied up will vary greatly based on factors we’ll discuss later, the typical building cost for a standard 2,600-square-foot home is between $140,000 and $700,000. These figures include all construction costs including labor, materials, equipment, plans, and building permits.  For this article, structures are classified by the quality of construction: economy, standard, and luxury. This categorization is based primarily on the cost of materials used in the construction of basic design elements—it does not necessarily reflect some features and construction details that make a home more beautiful and expensive. Economy quality is the minimum required under most building codes. Typically, homes in this class are characterized by reinforced concrete or concrete block foundation; floors made of standard wood frame; and roofs with wood frames, shingle or built-up cover, and open soffit. Meanwhile, structures of luxury quality are generally designed by professional architects and feature terrazzo, marble, or carpet flooring throughout; highly detailed complex tile, slate, or metal roofs; and interiors that tout decorative details and artistic finishes. This cost guide describes typical specifications that define the standard class. Most single-family homes and houses built from stock plans or offered by tract home developers fall under this category. These structures normally feature engineered wood floor structures, multi-pitch roofs, and large, closed soffit, as well as good-grade doors and windows. The Construction Cost Breakdown section of this article discusses more of these specifications in detail.

For this article, structures are classified by the quality of construction: economy, standard, and luxury. This categorization is based primarily on the cost of materials used in the construction of basic design elements—it does not necessarily reflect some features and construction details that make a home more beautiful and expensive. Economy quality is the minimum required under most building codes. Typically, homes in this class are characterized by reinforced concrete or concrete block foundation; floors made of standard wood frame; and roofs with wood frames, shingle or built-up cover, and open soffit. Meanwhile, structures of luxury quality are generally designed by professional architects and feature terrazzo, marble, or carpet flooring throughout; highly detailed complex tile, slate, or metal roofs; and interiors that tout decorative details and artistic finishes. This cost guide describes typical specifications that define the standard class. Most single-family homes and houses built from stock plans or offered by tract home developers fall under this category. These structures normally feature engineered wood floor structures, multi-pitch roofs, and large, closed soffit, as well as good-grade doors and windows. The Construction Cost Breakdown section of this article discusses more of these specifications in detail.

This beautiful custom home by JMJ Custom Homes in Owensboro, Kentucky boasts of a mixture of textures and patterns in both its exterior and interiors. With a cost range of $500,001 to $750,000, this Parade of Homes participant includes a one-of-a-kind game room with a distinct tray ceiling.

Each home type varies in terms of designs, building methods, and materials. These—in addition to building shape, floor area, and overall quality—make these buildings inherently very different and, accordingly, affect the final costs. The table below shows the building costs for each type of home. These include only the costs of building the actual structure and not the other costs associated with home construction, like permits and architectural fees—which can take up about 40% of the total final costs.

COST RANGE (per square foot)

$90 – $400

$60 – $115

$180 – $250

$125 – $250 (without finishes)

$100 – $400

| TYPE OF HOME | ||||

|---|---|---|---|---|

| Custom | Manufactured | Modular | Panelized | Log/Timber Home |

Cost to Build a Custom Home

Custom homes are often one-of-a-kind upscale homes that feature many unique architectural details. By building a custom home, you can tailor-fit your house’s features to suit any need, whether it’s additional bedrooms, a basement, specialty rooms, or a nice porch and garage. Building a custom home means you have total control over the design of your home. You’ll have the freedom to incorporate architectural styles you love, add features that fit your lifestyle—like an art studio or gourmet kitchen—or incorporate the latest trends and technology.

In building a custom home, you have the option to hire either an architect then bid the plans to contractors or have a negotiated bid where the architect and contractor come in at the same time to collaborate. The important thing to remember is to hire them early on in the process so they can work together to bring you the best plans and designs according to your budget. This will help you get feedback on pricing and avoid extra costs in overdesigns.

Get free bids from contractors ➜

| PRO TIP |

|---|

| Bring in your builder upfront. Avoid the temptation to work with an architect directly and shop the plans later. If you develop a team that you trust inherently, they’ll help you avoid some of the pitfalls that may otherwise throw your build off course. If you’re looking at multiple lots, having a builder in your corner can be a huge resource. They can walk those lots with you and help you determine which lot is best for your build. |

| – Danni Eickenhorst of Hibbs Homes |

The average cost of building a house shown above accounts for as much as 60% of the whole process cost. Hiring a professional interior designer to make your home look magazine-worthy with top-notch finishes, materials, and details can also mean an additional 10-15% depending on labor costs and types of materials. Meanwhile, other costs that should be considered are site preparation, utility lines, government fees and mandates, and finance costs—which can reach around 40%.

Back to Top

Cost to Build a Prefabricated Home

A prefabricated home is an encompassing term for homes that are made in a factory and built or assembled on site. This type of home can be bought whole or in parts. They can sometimes cost less than custom homes due to their pre-made nature, but high-end finishes can still increase the cost.

One reason why prefabricated homes are less expensive is construction can take place any time, which can also mean quicker turnaround times. This also makes for more efficient production, which results in economies of scale or a proportionate saving in costs due to an increased level of production. If you’re choosing a home that is not one-of-a-kind, then it’s cheaper by the unit to produce 10,000 of these than one highly-customized structure. Another reason for lower construction costs has to do with reducing uncertainties on-site, where one misstep can delay progress and balloon labor costs.

Choosing a prefabricated home can help you save up to 20% of your construction budget. Prefab homes can come in the form of manufactured, modular, or panelized homes.

Manufactured Homes – These are homes built entirely in a factory, transported to the site, and installed under a federal building code administered by the U.S. Department of Housing and Urban Development (HUD). Manufactured homes can typically cost half as much per square foot than new site-built housing construction.

Prices for manufactured homes can play around $37,000 to $270,000. In a HUD survey in 2018, the average size of a new manufactured home was 1,500 square feet. A home of this size can cost anywhere from $60 to $115 per square foot. For a standard 1,500-square-foot manufactured home with mid-grade finishes, expect to have a budget of around $120,000. This cost includes delivery to the site, setting on piers, finishing, connecting to utility lines, pulling permits, and performing inspections.

Find a builder you can trust ➜

A one-story manufactured home in California by Silvercrest

Modular Homes – These homes are built in sections (modules) at a factory. They are then transported to the site and assembled by local contractors. Usually built under 6 to 12 weeks, modular homes have a shorter build time that often minimizes the overall construction costs. Modular homes are also a great option for sustainable building since construction waste is kept at a minimum. The base price of buying a modular home with no customization or alteration can range from $180 to $250 per square foot. Fabrication, finishes, delivery, and assembly can cost $250 to $450 per square foot on average. Many modular home builders charge a much higher price due to their designer finishes.

A one-story modular home in Seattle by Stillwater Dwellings

Panelized Homes – These are customizable factory-built homes in which panels are transported to the site and assembled. Compared to modular homes that are 95% completed in the factory, panelized homes require more finishing work on site. Installation of other elements such as drywall and mechanical and electrical systems are completed by contractors on site. Harvest Homes, a leading New York panelized home company, puts the range of a standard panelized home at $125 to $250 per square foot. Again, site costs, land prices, and finishes can bump up costs.

A two-story panelized home in New Hampshire by Davis Frame Co.

Back to Top

Cost to Build a Log or Timber Frame Home

Log and timber frame homes put a premium on the natural look and feel of wood. They can assume many different styles while remaining recognizably log or timber. These types of homes are also customizable. Building a log or timber frame homes involves buying the wood or frame from a company that manufactures the pieces then hiring a builder to assemble them on site.

A finished log or timber frame home can range from $100 to $400 per square foot. This wide range accounts for the type of wood used, finishes, and other materials used inside the home. For mid-grade homes, $200 to $250 per square foot is the common range for most companies that do turnkey services, meaning they perform the full suite of manufacturing, assembling, and finishing the home.

Back to Top

Construction Cost Breakdown

Cost Breakdown for a Custom Home

Where you spend your money depends a lot on the type of home you choose. The chart below shows the typical breakdown of general home building costs. Each component includes all construction costs including labor, material, equipment, plans, and building permits. Construction expenses may represent up to 60% of the total cost, while site preparation, utility lines, government fees and mandates, and other finance costs may cost as much as 40%. This breakdown generally applies to many single-family homes constructed using conventional methods, but other factors such as unique features of the land or home can really affect these figures. For instance, if you live on a steep hill, you might spend 20% of your costs on grading and foundation just to have a solid base to work on.

DESCRIPTION

A foundation could be as simple as a concrete slab or as complex as a full basement. Other factors that affect the cost of such include preparing and excavating, concrete pouring, and backfilling, among others. Additionally, some homes require sealing, draining, humidifying, insulation, and other necessities, which can increase foundation costs.

Endurance, noise insulation, comfort, and cleaning effort come into play in the selection of floor structure and finish. For standard homes, floor structures are typically made of engineered wood or steel or reinforced concrete slab. Meanwhile, floor finishes can be any or a combination of simulated marble, good carpet, hardwood, and vinyl.

Wall framing includes the overall frame of the home, particularly the vertical and horizontal members of exterior walls and interior partitions, both of bearing walls and non-bearing walls. Framing costs cover these as well as trusses and general metal work. Meanwhile, exterior finishing prices depend on the number and type of siding, trim, doors, and windows. Good quality interior walls are typically made of gypsum wallboard with putty or texture coat finish. There are also decorative details in the living room, entryway, and kitchen. Meanwhile, the materials used for ceilings should be appropriate for a room’s purpose. You can select among common ceiling materials such as drywall, plaster, wood, tile, and metal.

The cost to install a roof depends on the size of the building as well as the material, but the figure above is the average cost for a multi-pitch, shake, tile, or flat roof with a large, closed soffit. The installation and upkeep of specialty roofs cost more than those made of asphalt, but durability must be considered over other factors.

Interior details pertain to features that add to the value and comfort of your home. For instance, an average home can have a cathedral ceiling at the entryway, several wall openings or pass-throughs, and a formal dining area.

The cost of bath and kitchen details vary widely depending on the type and quality of the materials used as well as the size of these spaces. Perhaps the most essential considerations are necessary furnishings such as a shower or tub, an eating area, and cabinets and countertops. If you have a tight budget, you might simply focus on making these rooms feel spacious by using paint.

The installation of plumbing and electrical systems comprise a majority of the costs of a new custom home. In addition to size, the type of system greatly affects the cost as each has disparate installation times and requires different levels of expertise. Likewise, ensuring that these systems are up to code also affect these costs.

These special features may include some potentially necessary additions and amenities that can increase the comfort and functionality of your home. These can mean having good built-in appliances, a walk-in pantry, a wet bar, and a central vacuum.

| ELEMENT | |||||||

|---|---|---|---|---|---|---|---|

| Foundation: $35,000 | Floor Structure: $47,000 Floor Finish: $20,000 | Wall Framing and Exterior Finish: $54,000 Interior Wall and Ceiling Finish: $31,000 | Roof: $39,000 | Interior Detail: $19,000 | Bath Detail: $15,000 Kitchen Detail: $31,000 | Plumbing: $46,000 Electrical System: $39,000 | Special Features: $12,000 |

Back to Top

Cost Breakdown for a Manufactured Home

Manufactured homes often look like trailers or mobile homes and are considered as affordable housing. While these structures are made of one or more sections intended to be delivered for erection, no wheels, axles, or towbars are included in these costs. These figures include costs such as delivery to the site, setting on piers, finishing, connection to utility lines, permits, and inspections.

Get free bids from contractors ➜

COST

$14,000

$22,000

$11,000

$6,000

$10,000

$8,000

$28,000

$17,000

$5,000

| ELEMENT | ||||||||

|---|---|---|---|---|---|---|---|---|

| Roof | Exterior Walls | Doors and Windows | Interior | Floors | Heating | Kitchen | Baths and Plumbing | Bedrooms |

Back to Top

Factors That Influence the Cost of Building a House

Get a free cost estimate

Homebuilding may be the single most expensive investment that a person can make in a lifetime. Your first home is where you spend a huge portion of your life, so you want to make sure that it’s built right the first time, especially since construction mistakes are costly. Building a home can also be an overwhelming exercise, and it might seem exciting to include all possible things at once. Heidi Kallett of Joy Design + Build shares what usually drives the costs during homebuilding.

Here are some of the factors that have the greatest impact on the cost of your new home.

Size and Shape

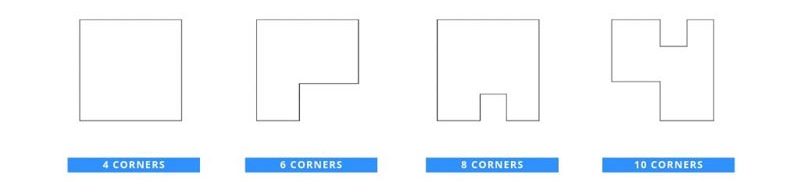

One of the first decisions you have to make in the process of planning your home is its size and general structure. Size covers square footage, number of stories, wall and ceiling heights, and number of rooms. Meanwhile, the home’s exterior shape and complexity also significantly influences the cost. Simply put, the bigger and more complex the home’s design, the more expensive it will be.

To illustrate, a simple 2,600-square-foot four-corner home will be cheaper than a ten-corner home of the same size.

Skycastle Construction, a leading custom home builder in Boulder, Colorado also sees size and shape as a huge factor in building homes.

Back to Top

Region and Location

While the national estimate for construction is at $150 per square foot, there are some areas in the country where construction costs can be more expensive or affordable. This is caused by the variance in the price of materials, labor, and building permits and fees in the area. For example, it is generally more expensive to build a new home in the Northeast than in the South. However, there are some outlying exceptions to this. Expect to pay more in major states like New York, California, Texas, Alaska, and Hawaii, where home construction costs can be 9% to 23% more expensive than the national average.

Data from the National Building Cost Manual 2019. Values reflected are construction costs per square foot for six-corner 2,600-square-foot homes.

Get free bids from contractors near you ➜

Back to Top

Land Characteristics

The characteristics of your plot of land can have a big impact on your budget. If your plot is on a slope, you may need to pay for grading, deeper foundations, or retaining walls to hold the foundation in place. If you plan to build your home in a remote area without utility connections, you may need to budget more for setting up basic utility systems such as sewage, water, and electricity. There are, at times, unforeseen costs associated with a plot of land; those who are preparing a foundation for a new home in rocky zones may find large boulders in their way that require special machinery to break up and remove.

A contractor that has seen this challenge up close is Hibbs Homes of St. Louis, Missouri.

| “They see an idyllic location—but our crews may see excessive tree clearing, topography issues, a need for septic and well systems, and the potential for a long driveway. These elements can use a lot of the client’s budget before we even break ground. Additionally, clients don’t often understand how design and finish choices greatly affect construction costs.” |

|---|

| – Danni Eickenhorst of Hibbs Homes |

Featured here is a 3,500-square-foot, two-bedroom custom home built by Missouri-based firm Hibbs Homes. Situated in a large wooded lot, the home was designed for the owners to age in place. A low-entry shower, wide doorways, and a three-season room perfect for an indoor-outdoor living are just some of the features of the luxury home.

The quality of your land also plays a significant role in budgeting for construction costs. It has the potential to make it easier or harder for the builders to construct your home depending on its features. An easy thing to watch out for is whether or not your home will be built on a slope, which could easily drive up your costs because it would require grading, deeper foundations, or retaining walls. However, great contractors could easily turn this site challenge into an asset. Done right, building your home on a slope could enhance your home’s exterior appeal and increase its market value.

Back to Top

Quality of Finishes

Every new homeowner would like to see their home in the most beautiful state possible. Finding the right finishes is possibly the most fun you’ll have while building your new home, but it is also where you’re most likely to overspend. Note that nearly half of the construction budget will go to the exterior and interior finishes—understandably so, since it’s the materials that will help define your home’s style and personality.

This Tuscan transitional home in Houston was designed and built by Jauregui Architects. Characterized by sophistication and elegance, its more than 8 million dollar price is driven by its luxury accoutrements and finishes. Travertine flooring, wood-beamed ceilings, arched doorways, and iron scrollwork can be seen all around.

The finishes’ importance in the homebuilding process is correlated to its impact on the total cost of construction. This depends mostly on the luxuriousness of your chosen materials.

| QUALITY OF MATERIALS AND FINISHES | |||

|---|---|---|---|

| ECONOMY | STANDARD | LUXURY | |

| FLOOR | Sheet vinyl, standard carpet, some tiles or hardwood | Simulated marble, good carpet, hardwood, or vinyl elsewhere | Terrazzo, marble, granite, inlaid hardwood, or best carpet |

| ROOF | Wood frame, shingle, or built-up cover | Multi-pitch, shake, tile, or flat surface | Complex plan, tile, slate, or metal; highly-detailed |

| WALL | Wood or steel, stucco or wood siding; few wall offsets | Wood or steel, several wall offsets, wood or masonry accents | Wood or steel, irregular walls, stone veneer |

| BATH | Average plastic tub and shower in at least one bathroom | Tile or fiberglass shower, one built-in bathtub | Custom large tile showers, separate elevated spa in master bath |

| KITCHEN | Stock standard grade wall and base cabinets, low-cost acrylic or laminated plastic countertop | Good stock wall and base cabinets, tile or acrylic countertop; breakfast bar or nook | Deluxe wall and base cabinets, stone countertop, island work area, breakfast bar |

Nick Bugbee of Bugbee Custom Home Builder, one of the premier custom home builders in the Las Vegas area, puts designs and quality of finishes as a large factor in the cost of building a home.

Get a free cost estimate ➜

| “If something is not designed around modular dimensions there is a lot of extra material needed, which turns into wasted material and money. Finishes are another large factor in the cost of the home. This includes everything from the brand selected for plumbing fixtures and appliances to the flooring and wall coverings to the cabinets.” |

|---|

| – Nick Bugbee of Bugbee Custom Home Builder |

This $9.5 million home in Nevada by Bugbee Custom Home Builder has a unique feature: rammed-earth walls. The lengthy and costly process involves color testing, layering of the material, and installation.

Back to Top

Additional Home Features

Installing optional features could easily runup your total bill. Adding a pool, for instance, can cost up to hundreds of thousands of dollars depending on the type—be it in-ground or above ground. Trey Garner of Garner Homes in Texas admits pools are expensive, as building these involves either working around or manipulating the surrounding land.

| “The topography in the Hill Country is the culprit here, also. When a client wants the pool relatively close to the level of the outdoor living areas, or even flush with those spaces, we are often building swimming pools and spas that are essentially built on top of the natural grade, rather than dug into the earth. In addition to the expense of building such a structure, the outer walls of the pool are often veneered with stone and stucco, which also adds cost.” |

|---|

| – Trey Garner of Garner Homes |

Other common features that could drive up the costs are decks, porches, extra storage buildings, and additional dwelling units.

Jauregui Architects in Houston is another luxury custom home builder that does ‘big-ticket items.’ At $400 to $500 per heated square foot, its homes are inclusive of all improvements.

Back to Top

Green and Sustainable Elements

Choosing to build a green home can significantly change the construction budget depending on the elements that you plan to include. Generally, it is more costly to build a green home, but costs less to operate. For example, the national average for building a net-zero home is at $274,000 versus the $240,000 national average for standard homes. While it is nearly 16% more expensive to build a net-zero home, it will result in more savings for the homeowners in the form of zero net energy consumption in the long run.

This modern contemporary masterpiece was created by Skycastle Construction in Colorado. The near-Net-Zero Energy home achieved LEED Platinum certification. It has 10kWh of solar panels discretely tucked onto the roof, a ground source heat pump and boiler, foam insulation, an ERV, Energy Star windows and appliances, all LED lights and water-conserving plumbing fixtures.

Back to Top

In the end, your project will have a unique cost depending on what you want in a home. This guide will help you lay out your budget and anticipate costs that you will encounter throughout the home building process. If you want to have the most accurate picture of how much it costs to build a home, it is best to talk to a contractor and get an estimate for your particular needs.

[/vc_column_text][/vc_column][/vc_row]